Sunday, October 19, 2025

It's pretty amazing how much time is spent just moving things around. Started the day by taking a desk out of the downstairs office and shifting the remaining two around. Moved one of the wire shelf racks in from the garage, and then sorted the remaining empennage parts, along with the skins, from the shop into the storage racks.

This is the unglamorous reality of aircraft construction—half the battle is logistics and organization. Can't work efficiently when you're constantly searching for parts or clearing workspace. The time spent on storage and workflow setup pays back in reduced frustration later.

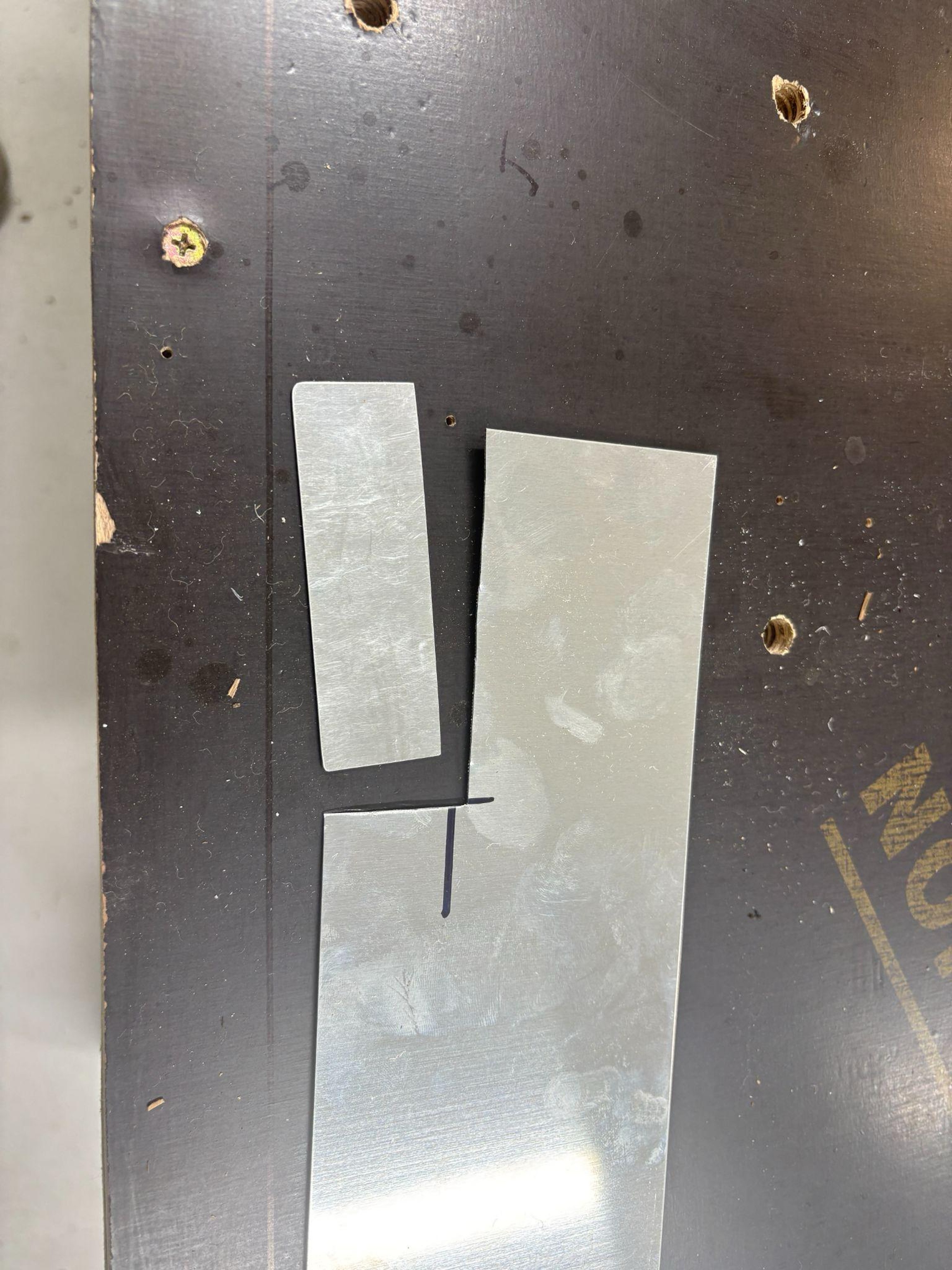

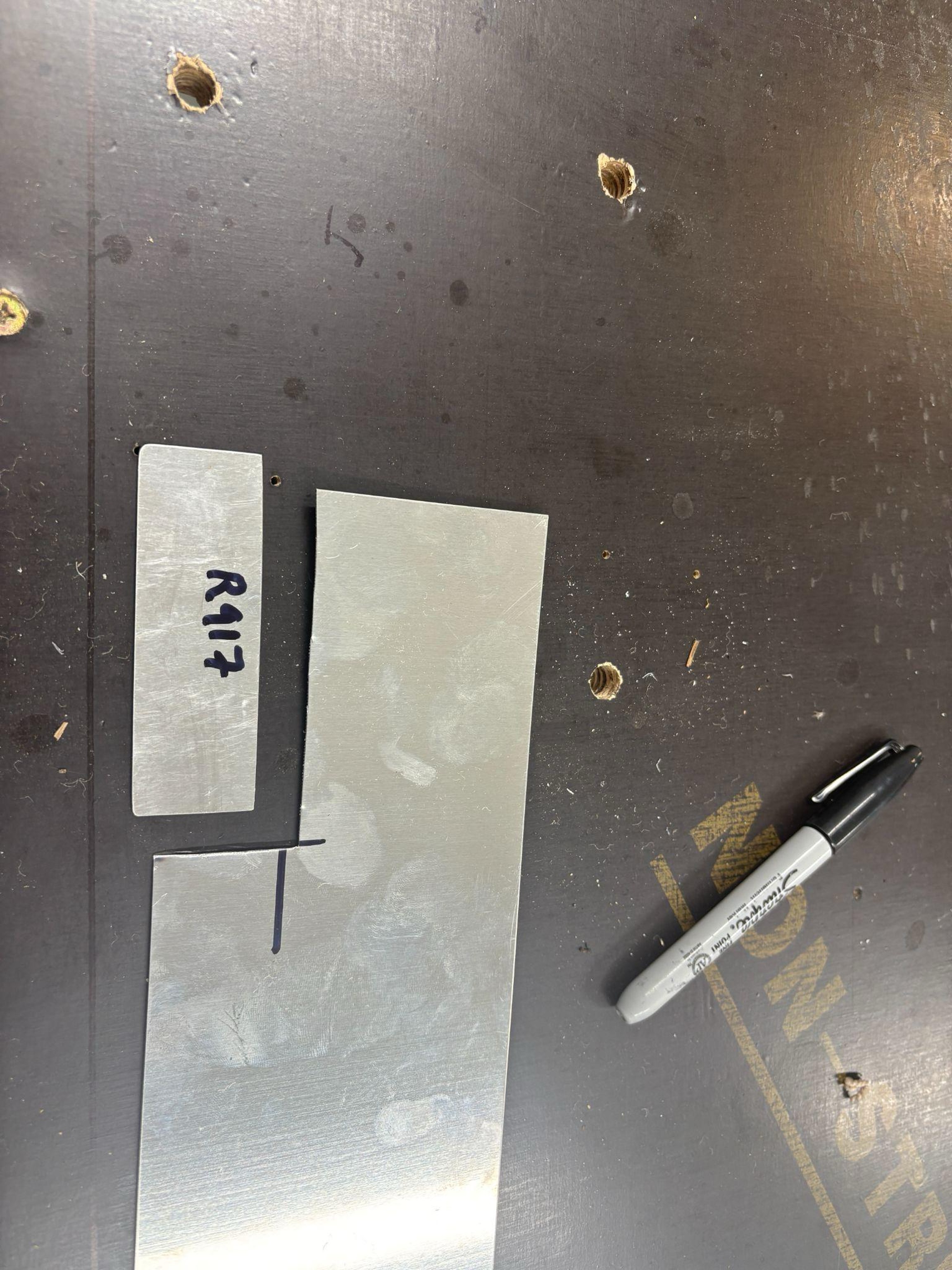

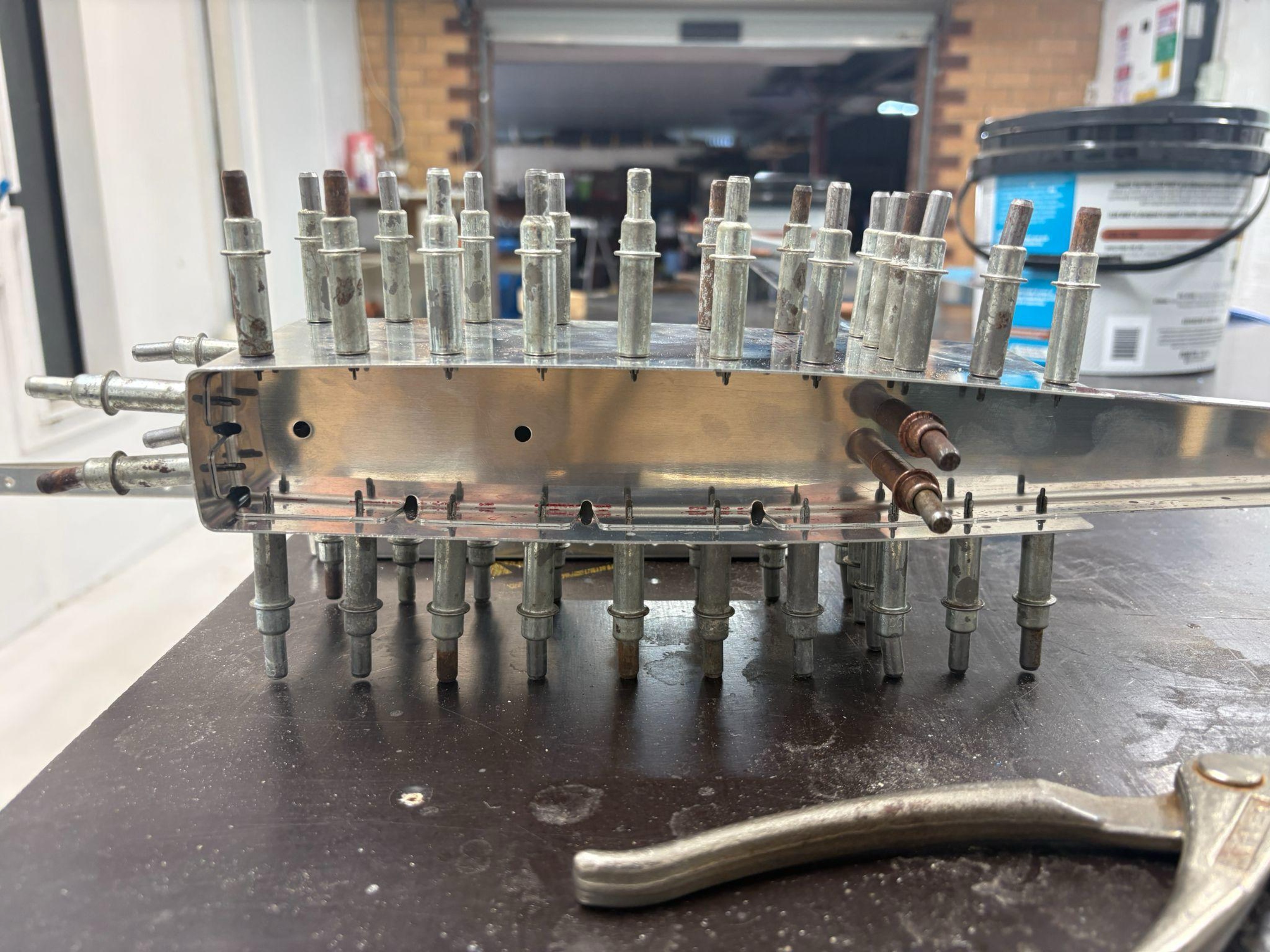

Spacer Fabrication

Setting up for spacer fabrication

Fabricating the spacers to spec

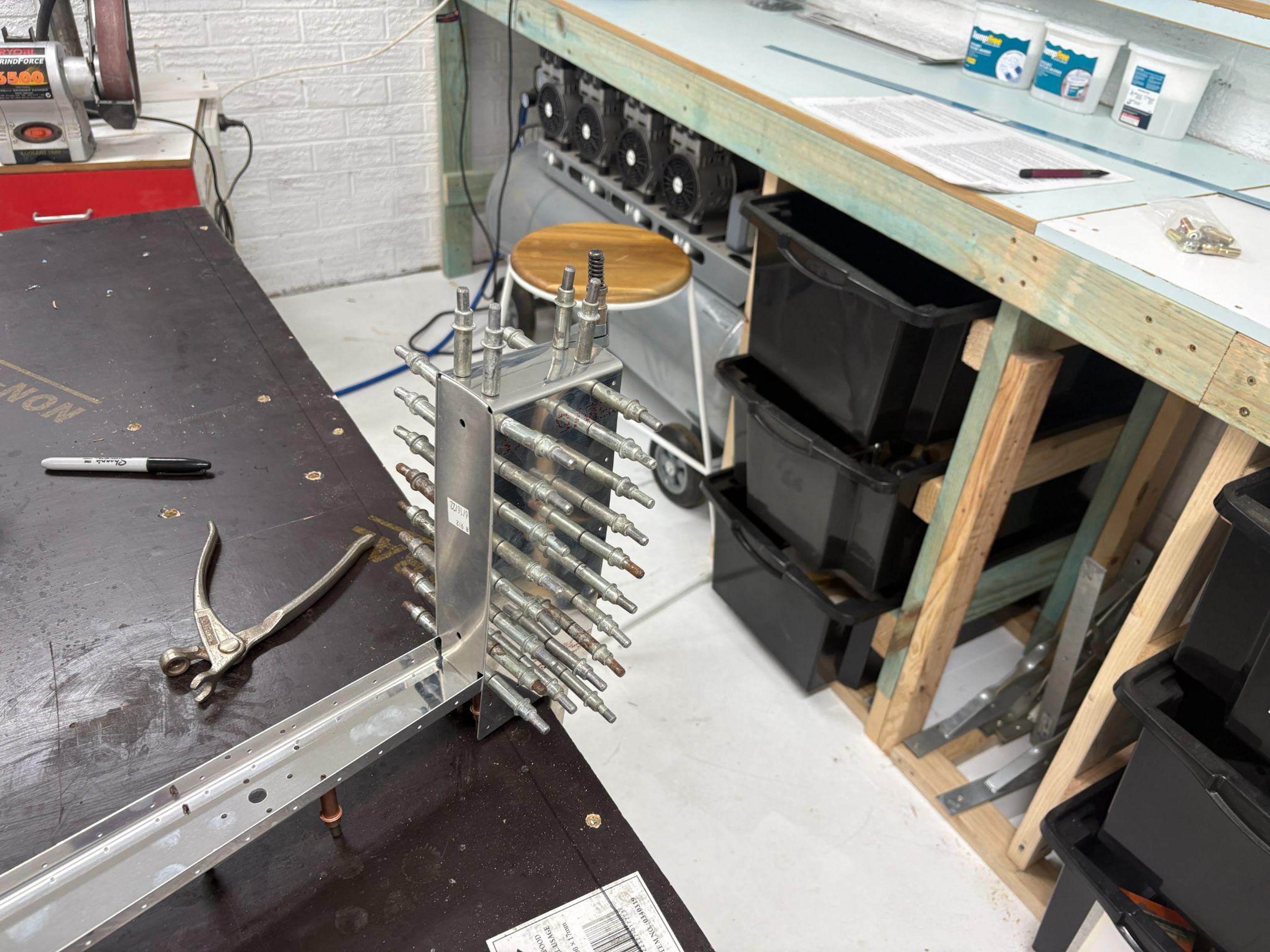

Placing spacers in position

Spacers installed and ready for skeleton assembly

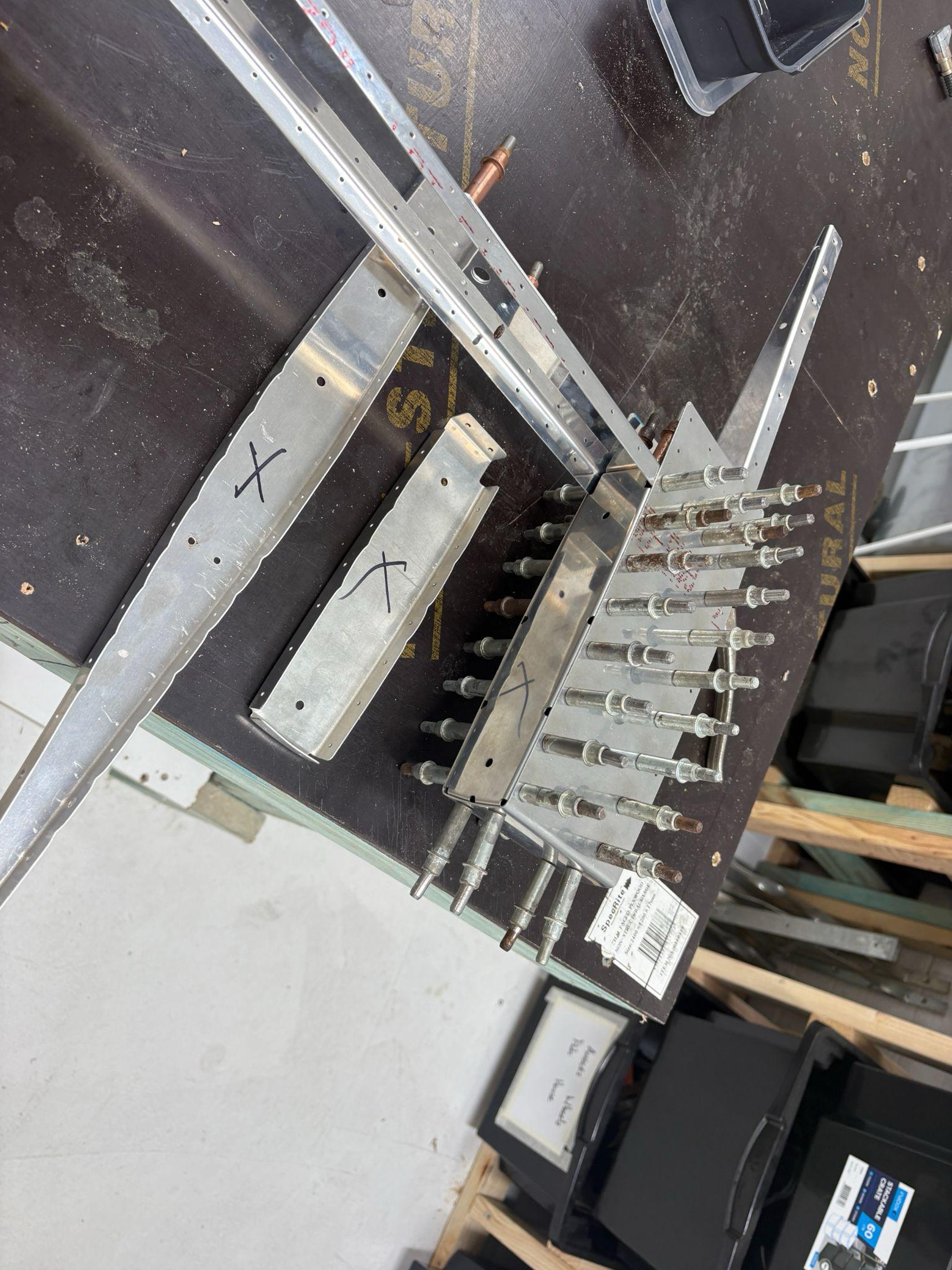

Skeleton Assembly

Rudder skeleton coming together

Skeleton assembly complete, ready for skin fitting

The Fluting Problem

Got the skeleton assembled and immediately discovered the front flange doesn't sit flush. This is one of those moments where you stare at the part, wondering if you've done something catastrophically wrong or if this is just normal aircraft building.

The front flange doesn't sit flush—gap visible

Turns out the solution is fluting—adding small waves to the metal to relieve stress and allow it to sit properly. This is one of those sheet metal techniques that sounds simple but requires practice to get right.

Adding fluting to relieve the stress

Reassembling to check the fit

Success—flange now sits flush

Sometimes aircraft building is just glorified metalwork. You're not designing complex aerodynamics or calculating structural loads—you're just bending metal until it fits properly. And that's fine. Every aircraft ever built required someone to make parts fit.